Wear, machine crash, failure:

Flexible and 3D manufacturing capacities

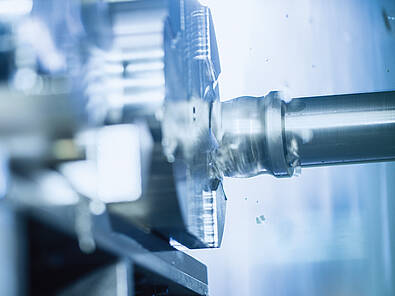

Experienced designers and cutting machine operators master the entire range of modern design Manufacturing

A state-of-the-art and innovative manufacturing facility covering more than 3,200 m² of manufacturing space as well as 1,200 m² of assembly area with gantry cranes are the spatial basis for the manufacturing of your spare parts and machine components. We are able to access a modern CNC machine park for turning, milling and deep-hole drilling at any time via our Jung group.

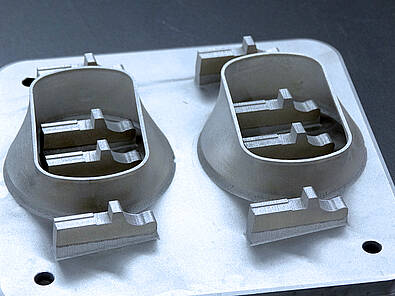

Additive manufacturing and laser measurement open up new perspectives

If conventional manufacturing with moulds or the conventional manufacturing method is out of the question, then we will be able to provide additive manufacturing (3D printing). With the new design and manufacturing concept, unavailable stainless steel components can now be produced in an extremely short time.