are safe with FAS Füllanlagenservice GmbH

Filling heights, material wear or mechanics - FAS is familiar with everyday practice

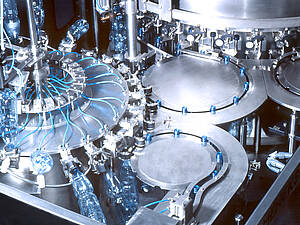

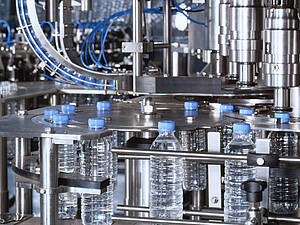

Still and CO2-containing beverages are bottled in systems which fill reusable bottles made of glass or PET as well as cans. Any kind of irregularity in the filling height is usually immediately indicated by the inspection machines. Interference diagrams are created so that one can react immediately.

Instances of malfunction are often caused by material wear or problems with the mechanical systems. For example, when a lever breaks or the bottle transportation system fails, there is a filling problem or seals no longer fulfil one hundred per cent of their task. FAS is familiar with everyday practice. We initially try to assist with error and fault analysis on the telephone and then, if necessary, equip our service technicians with the right spare parts for an assignment on-site.