Ideas for conversion or retrofit

Conversion of a filling system to FAS Neck-Handling-System

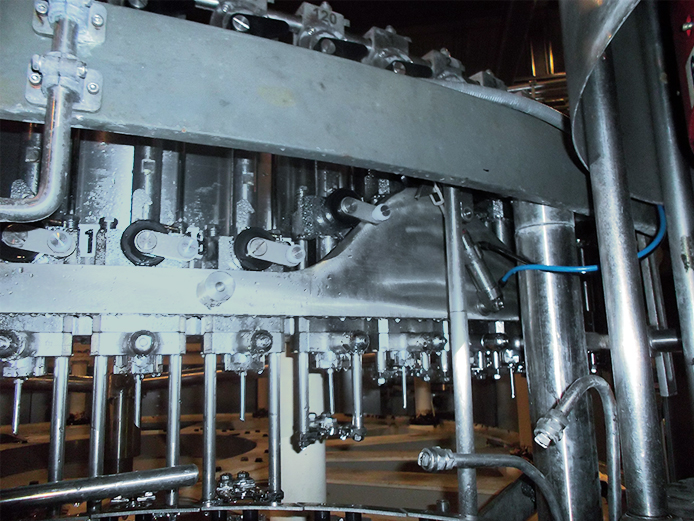

The plant for conversion was hereby a Hansa A120/20SV filling system model from O+H, which was built in 1979, with a filling capacity of 28,000 bottles per hour. The customer had purchased the system, which had already been equipped with a neck-handling system, some years before. However, the functionality of the installed neck-handling system proved to be unsatisfactory. In addition, servicing and maintenance works were intensive and therefore cost-intensive. The customer opted for a conversion to the FAS Neck-Handling System, which convinced them with its simplicity and easy overhauling capability. The following services were provided within a time period of less than two weeks

- Dismantling the existing filling valves and shipping to the factory in Kummerfeld.

- Parallel to the conversion of the filling valves in the factory, the fitters on site executed the assembly works for the control curves and switching devices on the machine.

- After just one week of processing time, the filling valves were back at the customer and were screwed onto the machine. Manufacturing was then able to start immediately.

- After small adjustment works, the machine operated with full capacity again.

The customer was very satisfied with the conversion works executed by FAS Füllanlagenservice and they also saved considerable costs by overhauling the filling valves. Meanwhile the annual overhauls are also being executed for the customer.