Ideas for conversion or retrofit

Conversion of a filling system to neck handling for PET bottles

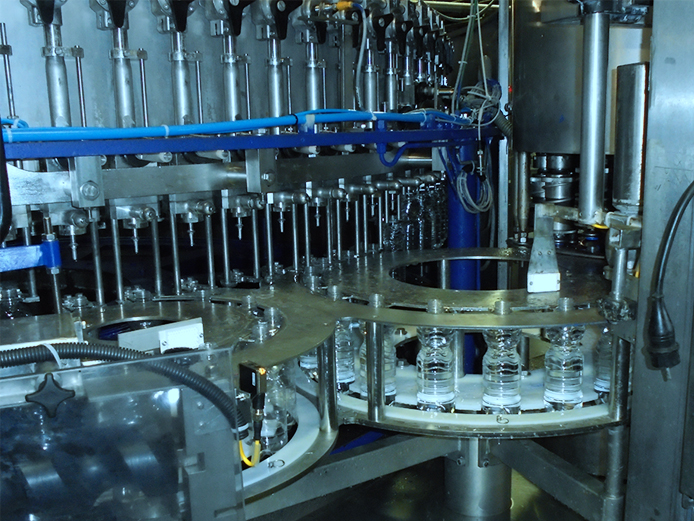

The customer´s Hansa A100/14SV model was an older O+H filler with a filling capacity of 24,000 bottles per hour, which was configured for glass bottles. This machine was however already processing PET disposable bottles. Since these bottles are naturally very light and soft, there had always been great problems with the handling of the PET bottles within the filler.

The task for FAS Füllanlagenservice was basically to completely convert the machine to neck handling. In doing so, all bottle guides as well as the other attachments on the front table should be manufactured of stainless steel. Furthermore, the press-on cylinders, which had previously been installed, should be dispensed with.

The following conversion measures were executed in a time frame of only just 2 weeks:

- Removing the existing press-on cylinder and re-cladding the bottle table with stainless steel sheets.

- Dismantling the filling valves and shipping to the factory in Kummerfeld.

- Overhaul and conversion of the filling valves in Kummerfeld to the FAS Neck-Handling System.

- Simultaneous dismantling of the steel and grey cast iron superstructures on the front table of the filler.

- Assembly of the new stainless steel components (transfer elements, transmission, lifting and lowering curve, ...)

- Returning the converted filling valves to the customer.

- Attaching the filling valves and adjusting the bottle transport transfers.

- In order to get the bottles arriving in the air conveyor to the machine division size of 112mm, two inlet screw worms were installed above each other.

As four different bottle formats should be filled, easy to interchange plastic segments were installed in different colours. Switching over to another bottle now takes only a few minutes.